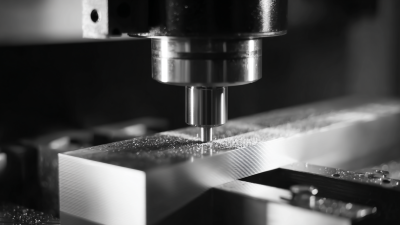

Top 10 Best CNC Machined Parts to Order for Your Projects in 2023

As the demand for precision engineering continues to soar, the CNC (Computer Numerical Control) machining industry remains a pivotal component in manufacturing across various sectors. According to a recent report by Grand View Research, the global CNC machining market is expected to reach USD 100.98 billion by 2027, growing at a CAGR of 6.5%. This growth is driven by the increasing need for customized parts and the advancements in automation and technology, allowing manufacturers to meet complex design requirements efficiently.

In this landscape, understanding which CNC machined parts to order is crucial for engineers and manufacturers aiming to optimize their projects. Whether you're in automotive, aerospace, or consumer electronics, the right machined components can not only improve product performance but also reduce production costs. This article outlines the top 10 best CNC machined parts to order for your projects in 2023, highlighting their applications, benefits, and industry trends to help guide your selection in a rapidly evolving market. Emphasizing quality and precision, these insights will be invaluable for those looking to leverage CNC machining capabilities for superior project outcomes.

Top 10 Essential CNC Machined Parts for Modern Engineering Projects

CNC machining has become an essential aspect of modern engineering projects, offering precision and versatility in the manufacturing of parts. Among the top essential CNC machined parts that engineers frequently require are brackets, mountings, and housings. These components are pivotal in ensuring structural integrity and functionality within various assemblies. Brackets, for instance, are often used for support and stabilization, providing a base that can withstand significant loads and stresses, while mountings are critical for attaching components securely. Housings, on the other hand, protect sensitive internal mechanisms from environmental factors, enhancing the durability of the overall design.

In addition to the common components listed above, specialized machined parts like gears, pulleys, and custom fittings play a crucial role in advanced applications. Gears are vital for power transmission and motion control, allowing for seamless mechanical interactions. Pulleys, which are often used in conveyor systems, leverage mechanical advantage to minimize effort in moving materials. Custom fittings, tailored to specific project requirements, enable engineers to optimize performance and compatibility within their systems. The precise manufacturing capabilities of CNC machining ensure these parts meet stringent specifications, making them indispensable in today's engineering landscape.

Innovative CNC Machined Components to Enhance Your Product Design

In 2023, the landscape of CNC machined components is marked by innovations that significantly enhance product design. Advanced manufacturing technologies such as additive manufacturing and smart manufacturing are revolutionizing how we approach CNC machining. These innovations not only improve precision but also contribute to sustainability efforts in various industries. Enhanced capabilities allow for more efficient use of materials and reduced waste, essential factors for modern production environments focused on environmental impact.

One notable trend is the integration of nanotechnology in CNC machining, which enhances the precision of manufactured components. This level of detail is crucial for industries pushing the boundaries of performance and functionality in product designs. Furthermore, the role of simulation software has become increasingly pivotal, allowing engineers to optimize designs without costly physical prototypes. As companies leverage these technologies, the potential for creating innovative machined parts grows, ensuring that 2023 is a year filled with opportunities for designers and manufacturers alike.

High-Precision CNC Parts You Should Consider for 2023 Prototypes

In 2023, the demand for high-precision CNC machined parts continues to surge, driven by advancements in technology and an increasing focus on efficiency in manufacturing. According to a recent report by MarketsandMarkets, the global CNC machining market is projected to grow from USD 63.46 billion in 2021 to USD 85.60 billion by 2026, at a compound annual growth rate (CAGR) of 6.1%. This growth highlights the critical role of precision components in modern prototypes.

When selecting CNC machined parts, engineers must consider materials that offer optimal performance under various conditions. Parts made from aluminum alloys, such as 6061 and 7075, are highly sought after for their excellent strength-to-weight ratio and corrosion resistance. Additionally, titanium components, although more expensive, are essential in industries like aerospace and medical devices due to their superior durability and biocompatibility. The Precision Metalforming Association notes that precision parts are increasingly vital in sectors requiring high tolerances and reliability, further emphasizing the necessity of utilizing high-quality CNC machined components in prototype development.

Top 10 Best CNC Machined Parts to Order for Your Projects in 2023

| Part Name | Material | Precision Level | Typical Applications | Estimated Cost (USD) |

|---|---|---|---|---|

| Aluminum Plate | 6061 Aluminum | ±0.005" | Aerospace, Automotive | $50 - $100 |

| Custom Bracket | Stainless Steel | ±0.002" | Manufacturing, Robotics | $30 - $75 |

| Gear Wheel | Carbon Steel | ±0.0015" | Automotive, Machinery | $20 - $50 |

| Pipe Fitting | Brass | ±0.005" | Plumbing, HVAC | $10 - $30 |

| Cable Clamp | Aluminum Alloy | ±0.005" | Electrical, Construction | $15 - $35 |

| Piston | Aluminium | ±0.002" | Engine, Machinery | $100 - $200 |

| Spindle Housing | Cast Iron | ±0.005" | Machinery, Industrial | $50 - $150 |

| Valve Body | PVC | ±0.01" | Fluid Control, Plumbing | $25 - $60 |

| End Cap | Polymer | ±0.01" | Sealing, Automotive | $5 - $15 |

| Heat Sink | Aluminum | ±0.005" | Electronics, Cooling | $20 - $40 |

Cost-Effective CNC Machined Solutions for Small Businesses

When it comes to small businesses looking to thrive in a competitive landscape, investing in CNC machined parts can be a game-changer. These precision-engineered components not only enhance product quality but also ensure consistency, making them an essential part of the manufacturing process. By ordering CNC machined parts, small businesses can significantly reduce waste and improve the overall efficiency of their production lines, leading to cost-effective solutions that do not compromise on quality.

Additionally, selecting the right CNC machined parts can streamline workflows and allow businesses to focus on innovation rather than heavy manufacturing. Components such as custom brackets, housings, and connectors offer versatility and can be tailored to specific project needs, helping small enterprises to minimize overhead costs while maximizing output. With the current technological advancements, CNC machining has become not only accessible but also affordable, positioning small businesses to take full advantage of these intelligent manufacturing solutions in 2023.

Trending CNC Machining Technologies and Their Impact on Component Quality

In 2023, the landscape of CNC machining is rapidly evolving, driven by advancements in technology that significantly enhance component quality. One notable trend is the integration of automated machining processes, which reduces human error and improves consistency in production. By employing sophisticated algorithms and machine learning, manufacturers can optimize tool paths and cutting conditions, ensuring that each part produced meets stringent quality standards. This technological progression not only boosts efficiency but also minimizes waste, leading to more sustainable manufacturing practices.

Another impactful trend is the adoption of advanced materials and coatings in CNC machining. Innovations such as titanium alloys and high-performance polymers enable the production of parts that are lighter yet stronger than ever before. Coupled with surface treatments like hard coating and anodizing, these materials enhance durability and resistance to wear, making them ideal for applications across various industries, from aerospace to medical devices. The convergence of these technologies positions CNC machining as a critical component in developing high-quality, reliable parts tailored to meet the specific demands of modern projects.

Related Posts

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

-

2025 Top 5 High Precision Machining Trends and Technologies Revolutionizing Manufacturing

-

2025 Top 10 5 Axis CNC Machines Revolutionizing Precision Manufacturing

-

Exploring High Precision Machining: Innovations Driving a $90 Billion Industry

-

Discover the Advantages of Using CNC Aluminum in Modern Manufacturing Processes

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing