Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

In today's fast-evolving manufacturing landscape, the role of CNC parts has emerged as a cornerstone of innovation, driving efficiency and precision across various industries. According to a report by Grand View Research, the global CNC machine market size was valued at approximately $70 billion in 2020 and is projected to expand at a CAGR of over 6% from 2021 to 2028. This surge underscores the increasing reliance on computer numerical control technology to produce intricate components that meet stringent quality standards. Companies that leverage advanced CNC machining techniques not only optimize their production processes but also enhance their competitive edge by reducing lead times and minimizing waste. As we explore the intricacies behind CNC parts, it becomes evident that understanding their application and innovation is vital for manufacturers aiming to succeed in a market that values rapid technical advancement and customization.

The Role of CNC Parts in Enhancing Precision Manufacturing Efficiency

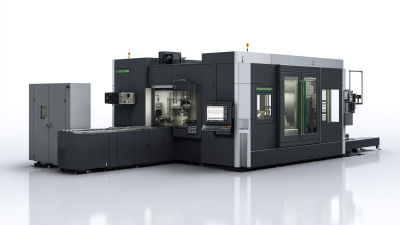

The integration of CNC parts into modern manufacturing techniques has significantly enhanced precision manufacturing efficiency across various industries. By leveraging advanced computer numerical control technology, companies are able to produce complex components with remarkable accuracy. This precision reduces material waste, shortens production cycles, and ultimately leads to higher quality products. As demonstrated by the advancements in CNC machining technology, manufacturers are not only achieving tighter tolerances but also improving their overall production capabilities.

Moreover, emerging technologies, including artificial intelligence and machine learning, are revolutionizing the CNC landscape. The application of these technologies empowers manufacturers to optimize their workflows and predict maintenance needs, which further enhances productivity. With the CNC machines market projected to grow substantially in the coming years, businesses are poised to invest in innovative solutions that improve their manufacturing efficiency and reduce downtime. Overall, the role of CNC parts in modern manufacturing techniques underscores a pivotal shift towards more precise and efficient production methods.

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

| Dimension | Value |

|---|---|

| CNC Machine Type | Vertical Machining Center |

| Max Speed (RPM) | 12000 |

| Accuracy (mm) | ±0.01 |

| Working Area (mm) | 1000 x 500 x 500 |

| Material Types | Aluminum, Steel, Plastics |

| Software Used | CAD/CAM |

| Applications | Aerospace, Automotive, Medical |

| Setup Time (hours) | 2 |

Key Innovations in CNC Technology Transforming Production Processes

The realm of modern manufacturing has witnessed a significant transformation, primarily driven by innovations in CNC (Computer Numerical Control) technology. One key advancement is the integration of artificial intelligence and machine learning into CNC systems. These technologies enable smarter decision-making processes, allowing machines to learn from patterns and optimize operations. This not only enhances precision but also reduces downtime by predicting maintenance needs, ultimately leading to increased productivity on the shop floor.

Another notable innovation is the development of advanced materials and cutting tools specifically designed for CNC machining. These materials enhance the durability and performance of CNC parts, allowing manufacturers to produce intricate designs with reduced wear and tear. Additionally, the use of multi-axis machining has expanded the possibilities for complex geometries, making it easier to create components that were previously difficult or impossible to machine. As a result, production processes are becoming more efficient and versatile, enabling manufacturers to meet the growing demand for customized solutions swiftly.

Comparative Analysis of Traditional vs. CNC Machining Techniques

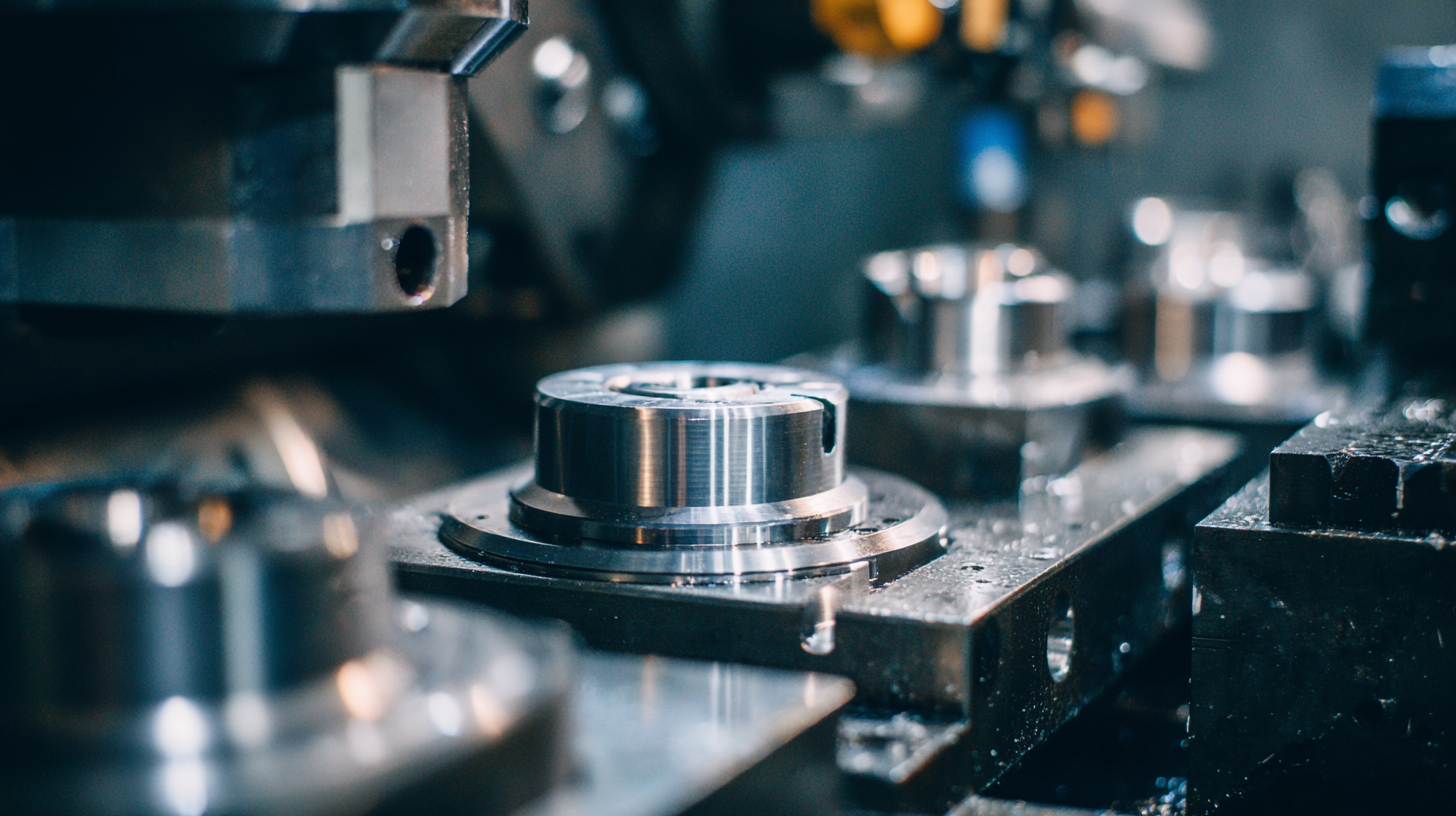

The evolution of manufacturing has witnessed a significant shift from traditional machining techniques to Computer Numerical Control (CNC) machining. Traditional methods, which often rely on manual operation and operator experience, can be time-consuming and prone to human error. In contrast, CNC machining utilizes computerized systems to automate the manufacturing process, resulting in enhanced precision, efficiency, and repeatability. This transition not only speeds up production time but also allows for complex part designs that were previously unmanageable with traditional machinery.

Tips: When considering a shift to CNC machining, evaluate the specific requirements of your projects. Investing in quality CNC equipment can significantly improve product consistency, and ensure that the parts manufactured meet stringent specifications.

Moreover, traditional machining methods often result in higher material waste due to limitations in design and processing capabilities. CNC techniques, however, are designed to minimize waste by optimizing material use, which is not only cost-effective but also environmentally friendly. As manufacturers adopt CNC technology, understanding these advantages can lead to more innovative solutions and greater competitiveness in the market.

Tips: Collaborating with experienced CNC operators during the initial phases of implementation can provide valuable insights, helping to streamline the transition and maximize the benefits of new technology.

Comparison of Traditional vs. CNC Machining Techniques

Impact of CNC Parts on Reducing Lead Times and Production Costs

CNC (Computer Numerical Control) technology has revolutionized modern manufacturing by significantly reducing lead times and production costs. According to a report by the American Society of Mechanical Engineers (ASME), companies utilizing CNC methods can achieve lead time reductions of up to 80%. This drastic decrease allows manufacturers to respond more swiftly to market demands, ultimately improving customer satisfaction. By automating the machining process, errors are minimized, leading to enhanced production efficiency and reduced waste, factors that are crucial in today’s competitive environment.

To maximize the benefits of CNC parts, manufacturers should invest in high-quality CNC machines and software that integrate seamlessly with existing systems. Additionally, regular maintenance is essential to ensure optimal performance and longevity of the equipment. As noted in a study by the National Institute of Standards and Technology (NIST), proper maintenance can extend the life of CNC machines by 30%, directly influencing production costs.

Incorporating CNC technology not only streamlines operations but also opens new avenues for innovation in product design. As manufacturers adopt more advanced CNC solutions, they can explore complex geometries that were previously difficult to produce, thereby enhancing their product offerings. Embracing this technology is crucial for staying competitive and fostering growth in an evolving market.

Future Trends: AI and Automation in CNC Manufacturing Solutions

The integration of AI and automation in CNC manufacturing is revolutionizing the production landscape, enhancing efficiency and precision. The global metal manufacturing market is projected to be valued at $82.09 billion in 2024, growing significantly to an estimated $1,008.18 billion by 2033, with a compound annual growth rate (CAGR) of 3.1% from 2025 to 2033. This growth is largely driven by advancements in automation technologies, which streamline operations and reduce labor costs, allowing manufacturers to meet the increasing demand for customized parts with shorter lead times.

In parallel, the global CNC controller market is also witnessing substantial growth, with projections indicating an increase from $33.66 million in 2025 to $228.7 million by 2033, fueled by a stable CAGR of 2.2%. As CNC controllers become more sophisticated with AI integration, they enable real-time monitoring and analytics, optimizing production processes and minimizing waste. This evolution not only enhances the quality of manufactured parts but also paves the way for smarter manufacturing solutions that align with the future of industry 4.0, where automation and intelligent systems play a central role.