Top CNC Machining Solutions for Precision Manufacturing in Industry?

In the fast-paced world of manufacturing, efficiency and precision are paramount. CNC machining solutions have emerged as key players in this landscape. These advanced techniques enable manufacturers to create intricate components with remarkable accuracy. Industries such as aerospace and automotive heavily rely on these technologies to meet their strict standards.

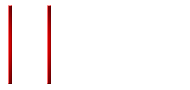

However, not all CNC machining solutions are created equal. Some may fall short of expectations, leading to costly setbacks. Manufacturers must carefully evaluate their options. They should consider factors like machine capabilities and software integration. Each choice impacts production quality and timing.

Moreover, companies often overlook maintenance. Neglect can hinder performance and lead to unexpected downtimes. It’s crucial to invest in regular checks to ensure machines function optimally. With the right CNC machining solutions and diligent maintenance, manufacturers can achieve the precision and reliability they strive for in their production processes.

Overview of CNC Machining in Precision Manufacturing

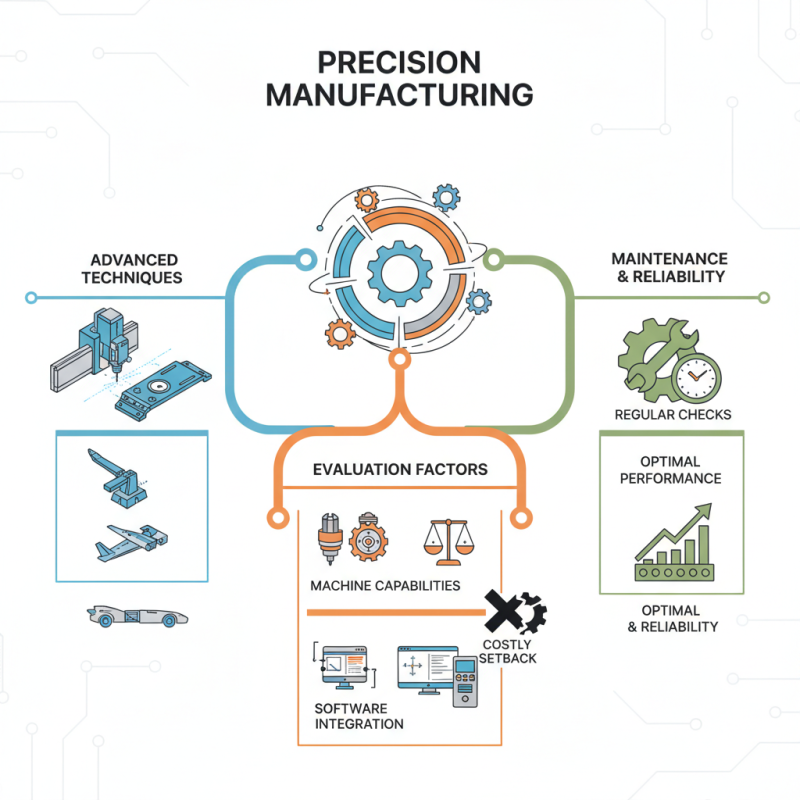

CNC machining plays a crucial role in precision manufacturing. It allows industries to produce complex parts quickly and accurately. According to a recent report by a leading industry analyst, the global CNC machining market was valued at approximately $56 billion in 2022. This figure is expected to grow substantially, signaling a rising demand for precision components across various sectors.

One key advantage of CNC machining is its ability to create intricate designs with tight tolerances. Parts can be manufactured with precision levels reaching +/- 0.001 inches. This is especially important in industries such as aerospace and automotive, where even minor deviations can lead to significant issues. However, there remains a challenge. Many manufacturers struggle to fully leverage this technology, often due to a lack of skilled workforce.

Tip: Investing in training programs can enhance your team's CNC skills. Regular workshops can bridge the gap in knowledge.

Moreover, automation in CNC machining reduces production costs and time. Yet, some companies still rely heavily on manual processes, which can lead to inefficiencies. A report indicated that automating just one aspect of the CNC workflow can yield a time-saving of up to 30%. Businesses must reflect on their practices to identify areas for improvement.

Tip: Regularly audit your CNC processes. Evaluate what can be automated for better efficiency.

Key Advantages of CNC Machining for Industrial Applications

CNC machining has become a game changer in precision manufacturing. A study by MarketsandMarkets indicates that the CNC machining market is projected to reach $100 billion by 2025. This growth showcases the technology's relevance and efficiency in industrial applications. Operators can produce intricate parts with high accuracy. This reliability leads to reduced material waste and lower production costs.

One key advantage of CNC machining is the ability to repeat complex designs consistently. According to a report by Research and Markets, companies using CNC technology have experienced a 30% increase in manufacturing productivity. Consistency is crucial for industries such as aerospace and automotive, where precision is vital. However, it is important to note that high initial setup costs may pose a barrier for smaller businesses.

Tips: Invest in training for your operators. Skilled hands maximize CNC capabilities. Regular maintenance of machines also enhances production efficiency. While CNC machining offers many benefits, not every component may be suitable for this method. Some parts may require traditional techniques. Assess your production needs carefully to make informed decisions.

Top CNC Machining Solutions for Precision Manufacturing in Industry

This chart illustrates the key advantages of CNC machining in industrial applications, highlighting attributes such as accuracy, speed, material versatility, cost efficiency, and waste reduction. These metrics showcase the benefits that CNC machining can bring to precision manufacturing.

Types of CNC Machines Used in Precision Manufacturing

CNC machines play a crucial role in precision manufacturing. They offer various types designed for specific applications. Milling machines, for instance, are ideal for shaping materials like metal and wood. These machines use rotary cutters for high accuracy. According to a report by MarketsandMarkets, the CNC machining market is expected to reach $100 billion by 2025.

Another key type is the CNC lathe. It rotates the workpiece against a cutting tool. This process is essential for creating symmetrical parts and complex shapes. CNC plasma cutters are also gaining popularity. They provide high-speed cutting for metal sheets, delivering clean edges. Yet, the choice of machine can significantly affect production quality and costs.

Tips: Always assess your specific manufacturing needs. Consider the type of material and desired precision. Investing in the wrong machine can lead to inefficiencies. Many manufacturers overlook maintenance needs. Neglecting this can cause delays in production and increased costs. Regular checks on equipment ensure consistent quality.

Top CNC Machining Solutions for Precision Manufacturing in Industry

| Type of CNC Machine | Primary Use | Material Compatibility | Precision Level | Typical Applications |

|---|---|---|---|---|

| CNC Milling Machine | Cutting and shaping materials | Metal, Plastic, Wood | ± 0.005 mm | Aerospace, Automotive Parts, Molds |

| CNC Lathe | Turning operations | Metal, Composite Materials | ± 0.01 mm | Shafts, Bearings, Bushings |

| CNC Laser Cutter | Precision cutting | Metal, Wood, Acrylic | ± 0.1 mm | Signage, Fabrication, Art |

| CNC Router | Carving and milling | Wood, Plastic, Foam | ± 0.02 mm | Furniture, Sign Making, Prototyping |

| CNC Plasma Cutter | Cutting thick materials | Metal, Steel, Aluminum | ± 0.5 mm | Metal Fabrication, Construction |

Emerging Technologies in CNC Machining Solutions

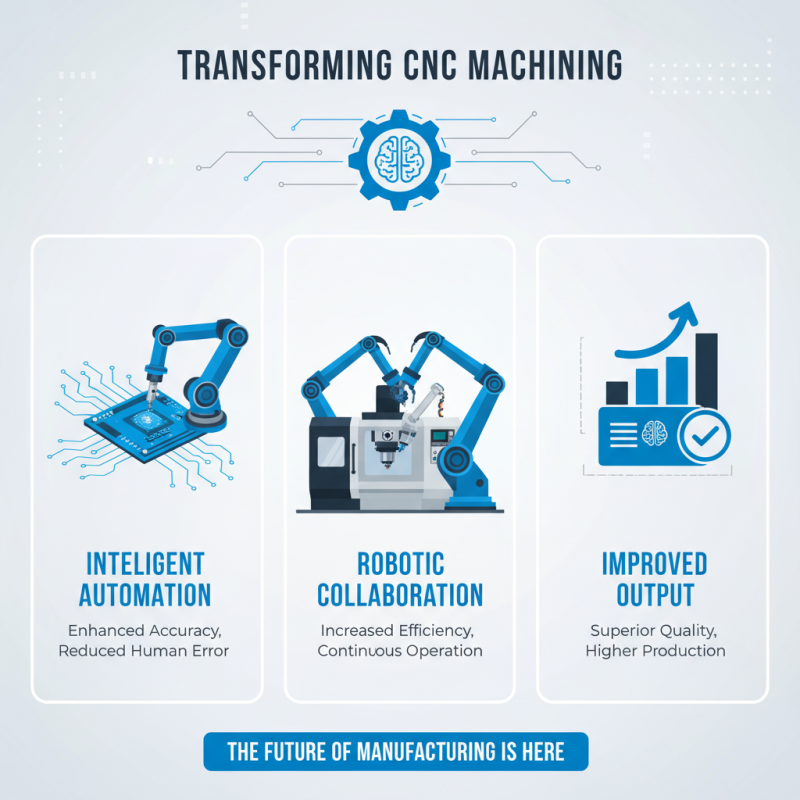

Emerging technologies are transforming CNC machining solutions. Intelligent automation enhances accuracy. Robots operate alongside machines, increasing efficiency. These advancements reduce human error and improve output quality.

Additive manufacturing is another key player. It allows for complex geometries that traditional methods cannot achieve. This technology often leads to material savings and faster prototyping. However, there is still a learning curve involved. Not every shop is equipped to handle these innovations smoothly.

Data analytics plays a crucial role too. Real-time monitoring helps predict maintenance needs. Yet, many manufacturers struggle to integrate these systems effectively. The challenge lies in deciphering vast amounts of data for actionable insights. Often, solutions may not address specific production needs. Implementing emerging technologies in CNC machining certainly requires careful consideration and adaptation.

Best Practices for Implementing CNC Machining in Industry

CNC machining has revolutionized precision manufacturing. Implementing it effectively requires careful planning and execution. Proper integration of technology can enhance productivity significantly. Yet, many struggle with common pitfalls.

Tips: Train your team thoroughly. Understanding CNC technology is vital for success. Regular workshops can bridge knowledge gaps. Encourage feedback from operators. They can provide insights into daily challenges. Addressing these issues early on is crucial.

Another best practice is to optimize the workflow. Layout matters—arranging machines for efficiency can save time. However, it's common to overlook this aspect. Analyze current workflows regularly. Small adjustments can lead to major improvements.

Tips: Use simulation software to visualize changes. This can reduce mistakes and waste. Also, maintain regular maintenance schedules. Neglect can lead to downtime, decreasing overall productivity. Finding balance is key to mastering CNC.

Related Posts

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

What is CNC Machining? A Comprehensive Guide to the Basics and Applications

-

How to Choose the Best Precision CNC Machining Services for Your Project

-

How to Choose the Right CNC Machine for Your Manufacturing Needs

-

How to Choose the Right CNC Machine for Your Projects and Budget

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques