What is CNC Machining? A Comprehensive Guide to the Basics and Applications

CNC machining, or computer numerical control machining, is revolutionizing the manufacturing industry by providing precision, efficiency, and flexibility in the production process. According to a recent report by Allied Market Research, the global CNC machining market is projected to reach $100 billion by 2026, with a compound annual growth rate (CAGR) of 6.4%. This growth is driven by increasing automation demands and advancements in technology, illustrating the integral role CNC machining plays in modern manufacturing.

As expert Dr. Jane Harmon, a leading authority in industrial automation, states, "CNC machining is no longer just a tool for high-end applications; it has become an essential component for any manufacturer looking to improve quality and reduce lead times." This highlights how CNC machining has expanded beyond traditional fields, making it accessible for a variety of industries, from aerospace to medical device manufacturing. By leveraging CNC technology, businesses can streamline their operations and maintain a competitive edge in an increasingly global market.

In this comprehensive guide, we will explore the fundamentals of CNC machining, its diverse applications, and how it continues to shape the future of the manufacturing landscape. Through understanding its principles and benefits, manufacturers can unlock the potential of CNC machining to drive innovation and efficiency within their operations.

Definition and Overview of CNC Machining

CNC machining, or Computer Numerical Control machining, is a manufacturing process that utilizes computer software to control machine tools. This technology allows for high precision and efficiency in producing complex parts and components across various industries, including aerospace, automotive, and electronics. According to a report by Grand View Research, the global CNC machine market was valued at approximately $63 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028. This growth is driven by the increasing demand for advanced manufacturing techniques and automation.

The core of CNC machining involves the use of CAD (Computer-Aided Design) files that guide the machining processes, which can include milling, turning, drilling, and grinding. This method significantly reduces human error and increases production rates. Additionally, a study from Deloitte indicates that CNC machining reduces waste by 30% compared to conventional machining methods, making it a more sustainable choice for manufacturers. As industries seek to enhance productivity and maintain quality standards, CNC machining has become an integral part of modern manufacturing.

Fundamental Principles and Processes in CNC Machining

CNC machining, at its core, involves a computer-controlled process that delivers precise manufacturing capabilities across various industries. This technology utilizes programmed commands from a computer to manipulate tooling and machinery, enabling the creation of complex designs with unparalleled accuracy. Fundamental principles of CNC machining include the use of CAD (Computer-Aided Design) for design creation and CAM (Computer-Aided Manufacturing) for generating the codes that drive the machines. This synergy is what makes modern manufacturing faster and more efficient compared to traditional machining methods.

When considering the applications of CNC machining, the versatility it offers is noteworthy. From creating intricate components for medical devices to crafting architectural features in Gothic monasteries, CNC machining serves as a bridge between innovation and tradition. For those exploring the world of CNC, here are a couple of tips: First, start with a solid understanding of CAD programs, as they are essential in transitioning from design to production. Secondly, consider the materials you wish to work with; knowing their properties will greatly influence your machining strategy and outcomes.

CNC Machining Applications in Various Industries

Common Materials Used in CNC Machining

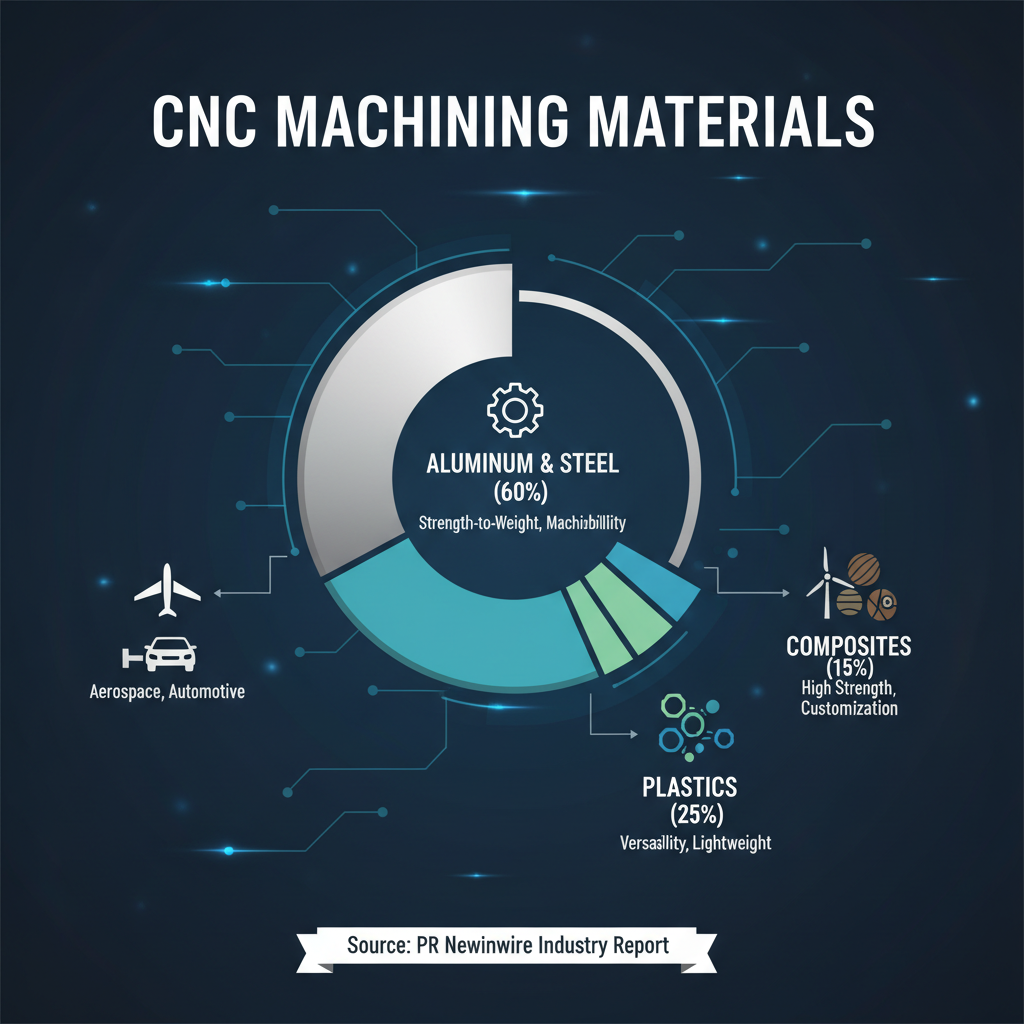

CNC machining, known for its precision and efficiency, relies on a variety of materials to meet diverse application needs. Among the most common materials used in CNC machining are metals, plastics, and composites. According to a recent industry report by PR Newswire, aluminum and steel occupy nearly 60% of the CNC machining market due to their favorable strength-to-weight ratios and machinability. Aluminum, in particular, is favored for its lightweight properties and corrosion resistance, making it ideal for industries such as aerospace and automotive.

Plastics are increasingly popular in CNC machining, accounting for approximately 25% of the material usage in the sector. High-density polyethylene (HDPE) and polycarbonate are frequently chosen for their durability and ease of processing. The rise in demand for lightweight components and cost-effective solutions has driven the adoption of plastics in fields like consumer electronics and medical devices. Furthermore, composite materials, though representing a smaller segment, are gaining traction due to their superior strength and flexibility, making them essential for specialized applications in high-performance sectors such as aerospace and defense. As the CNC machining landscape evolves, the choice of materials continues to play a crucial role in enhancing manufacturing capabilities.

Applications of CNC Machining in Various Industries

The adoption of CNC machining technology has revolutionized various industries by enhancing productivity and precision in manufacturing processes. Reports indicate that the global CNC tool grinders market is projected to grow at a compound annual growth rate (CAGR) of 6.3% through 2034, driven mainly by the increasing demand for high-precision tooling. As industries such as aerospace, automotive, and medical devices continue to prioritize quality and efficiency, CNC machining has become integral to their operations.

Recent advancements in CNC machining technologies have enabled facilities to produce high-quality components, particularly in stainless steel. Companies have reported significant improvements in productivity and output quality, showcasing the capability of CNC machines to meet rigorous industry standards. For instance, the introduction of high-precision machine tool robots has further bridged the gap between traditional CNC processes and industrial robotics, leading to greater automation and optimization in manufacturing workflows. With these innovations, sectors are not only meeting current demands but also setting the stage for future advancements in production capabilities.

Applications of CNC Machining in Various Industries

| Industry | Application | Materials Used | Benefits |

|---|---|---|---|

| Aerospace | Production of complex components | Titanium, Aluminum | High precision, lightweight |

| Automotive | Manufacturing engine parts | Steel, Plastic, Aluminum | Durability, cost efficiency |

| Medical Devices | Creation of surgical instruments | Stainless Steel, Titanium | Sterilizable, precision |

| Electronics | Production of housings and enclosures | Aluminum, Plastics | Lightweight, customizable |

| Construction | Fabrication of components for structures | Steel, Concrete | Strength, precision fitting |

Advantages and Challenges of CNC Machining Techniques

CNC machining, or Computer Numerical Control machining, offers several significant advantages that make it a preferred choice in manufacturing. One major benefit is its ability to produce highly precise and complex parts with minimal human intervention. This consistency in quality saves time and reduces the margin for error, ultimately leading to lower production costs. Additionally, CNC machines can operate continuously, allowing for increased efficiency and quicker turnaround on projects.

However, there are challenges associated with CNC machining techniques. The initial investment in advanced CNC equipment can be substantial, which may deter smaller businesses. Furthermore, the technology requires skilled operators who understand software programming as well as the machining process itself. Maintaining and troubleshooting these machines can also pose issues, especially if parts wear out or become damaged.

**Tips:** When considering CNC machining for your projects, assess your specific needs and the materials you plan to use. Additionally, investing in training for your team can maximize the benefits of CNC technology while minimizing potential downtime due to operator errors. Establishing regular maintenance schedules for your CNC equipment can also help prevent unexpected issues and prolong machine life.

Related Posts

-

10 Essential Tips for Mastering CNC Precision Machining Techniques

-

How to Choose the Best Precision CNC Machining Services for Your Project

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

2025 Top 10 5 Axis CNC Machines Revolutionizing Precision Manufacturing

-

Top 10 Best CNC Machined Parts to Order for Your Projects in 2023