Top 10 Benefits of CNC Aluminum Machining for Your Next Project

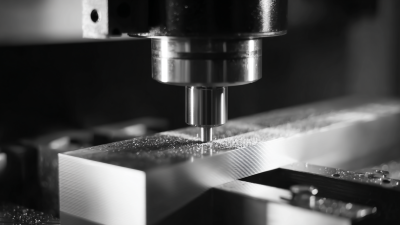

In the rapidly evolving landscape of manufacturing, CNC aluminum machining has emerged as a pivotal technology that enables precision and efficiency in producing intricate parts. According to John Stevens, a leading expert in the CNC aluminum industry, “The fusion of computer technology and aluminum machining has revolutionized the way we approach design and production, offering unmatched accuracy and speed.” This innovative process not only enhances productivity but also reduces material waste, making it an attractive option for manufacturers across various sectors.

As industries strive for optimization and sustainability, understanding the key benefits of CNC aluminum machining becomes increasingly important for project leaders and decision-makers. From lightweight yet robust components to cost-effective production methods, the advantages are manifold. Whether you are in aerospace, automotive, or electronics, leveraging CNC aluminum technology can significantly improve your project's outcomes. In this article, we will explore the top 10 benefits of CNC aluminum machining, providing insights that can help you make informed decisions for your next manufacturing endeavor.

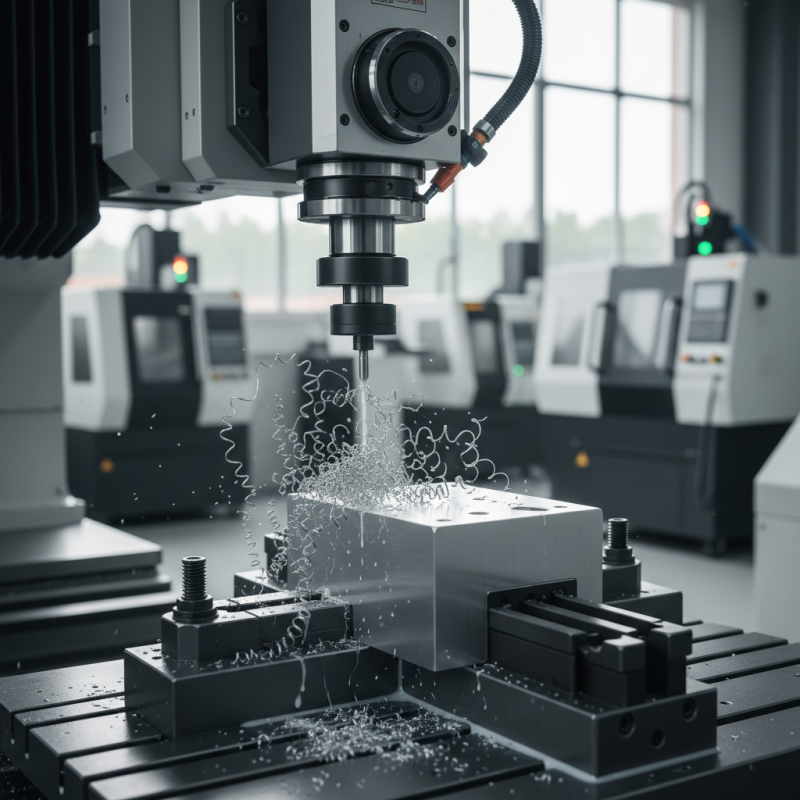

Benefits of Precision in CNC Aluminum Machining for Manufacturing

Precision plays a crucial role in CNC aluminum machining, significantly influencing the quality and efficiency of manufacturing processes. By leveraging advanced technology and computer-controlled operations, CNC machining ensures that every component is produced with exact specifications. This high level of precision minimizes tolerances, resulting in parts that fit together perfectly and perform reliably in their intended applications. Whether it’s aerospace, automotive, or electronics, precision in CNC machining allows manufacturers to meet stringent industry standards and improve overall product performance.

Moreover, the precision afforded by CNC aluminum machining leads to considerable time and cost savings during production. By automating the machining process, manufacturers can reduce manual labor while increasing the speed of part production. This not only shortens lead times but also allows for more complex designs to be realized without sacrificing quality. The ability to consistently reproduce high-accuracy parts also translates to fewer errors and reworks, further enhancing operational efficiency and reducing waste in the manufacturing workflow. Ultimately, the benefits of precision in CNC aluminum machining empower businesses to innovate and remain competitive in today's fast-paced market.

Enhanced Design Flexibility in CNC Aluminum Machining Projects

CNC aluminum machining offers significant advantages, particularly in terms of design flexibility, which is critical for modern engineering projects. The remarkable versatility of CNC technology allows designers to create intricate geometries and complex shapes that traditional manufacturing methods simply cannot achieve. According to a report from the International Journal of Advanced Manufacturing Technology, CNC machining can reduce production times by up to 50% compared to conventional methods, providing engineers with the freedom to experiment with innovative designs without the fear of excessive lead times.

Moreover, the use of advanced CNC aluminum machining capabilities can lead to a noteworthy reduction in material wastage. A study published by SME (Society of Manufacturing Engineers) highlighted that machine tools incorporating CNC technology can improve material utilization rates by over 20%. This not only conserves valuable materials but also allows for designs that are more lightweight and efficient, ensuring that the final products adhere to stringent performance specifications while remaining cost-effective. As industries continuously evolve towards sustainability and efficiency, the design flexibility offered by CNC aluminum machining becomes a pivotal factor in achieving successful project outcomes.

Top 10 Benefits of CNC Aluminum Machining for Your Next Project

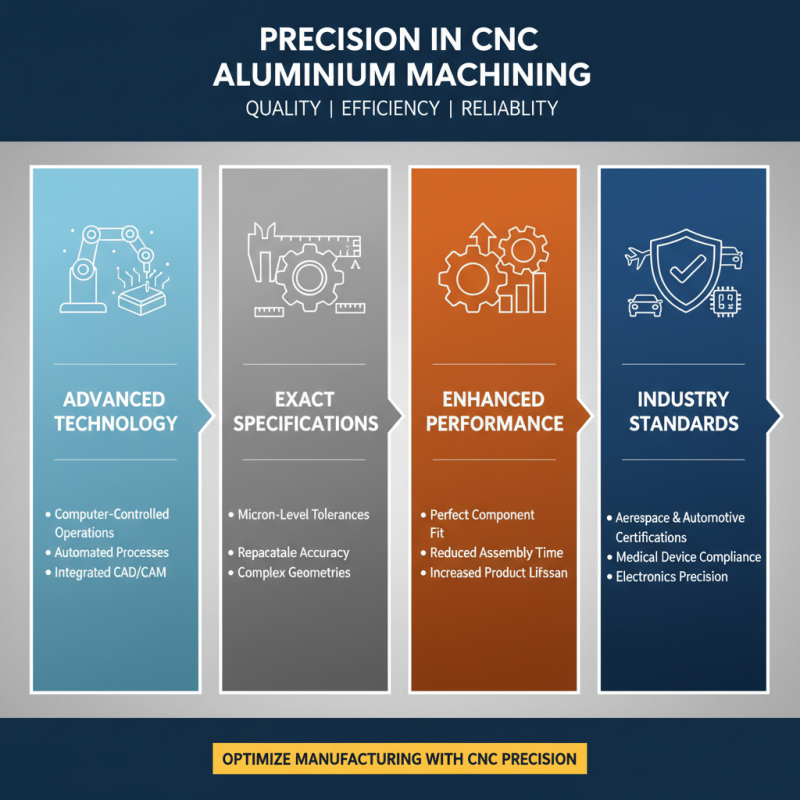

Cost Efficiency: Saving Time and Resources with CNC Aluminum

CNC aluminum machining offers significant cost efficiency, making it an ideal choice for various manufacturing projects. By automating the machining process, businesses can dramatically reduce labor costs and minimize the likelihood of human error. With CNC technology, complex components that once required extensive manual labor can now be produced quickly and accurately. This leads to substantial savings not only in time but also in the resources associated with materials and energy consumption.

Another key aspect of cost efficiency is the reduction of waste. CNC machining is exceptionally precise, meaning that the material is utilized more effectively, leaving less scrap compared to traditional machining methods. This precision allows companies to maximize their material investments, ensuring that each dollar spent on aluminum results in high-quality, usable parts. Consequently, companies can allocate their resources more strategically, potentially reinvesting the savings into other areas of their projects.

Improved Surface Finish Quality Achieved Through CNC Aluminum Processes

CNC aluminum machining is renowned for its ability to achieve superior surface finish quality, making it a popular choice for a variety of industries. The precision of CNC machines allows for intricate designs to be produced with remarkable accuracy, resulting in smooth and visually appealing surfaces. This is particularly beneficial in applications where aesthetics are critical, such as in automotive or consumer electronics, where a polished look can enhance product appeal.

Moreover, the improved surface finish obtained through CNC aluminum processes contributes to enhanced performance and durability. An even surface reduces friction and wear, leading to a longer lifespan of the machined components. This level of finish is also essential for components that require further processes such as anodizing or painting, as it ensures better adhesion and uniformity. Consequently, investing in CNC aluminum machining not only elevates the visual quality of products but also plays a vital role in optimizing their operational effectiveness.

Top 10 Benefits of CNC Aluminum Machining for Your Next Project

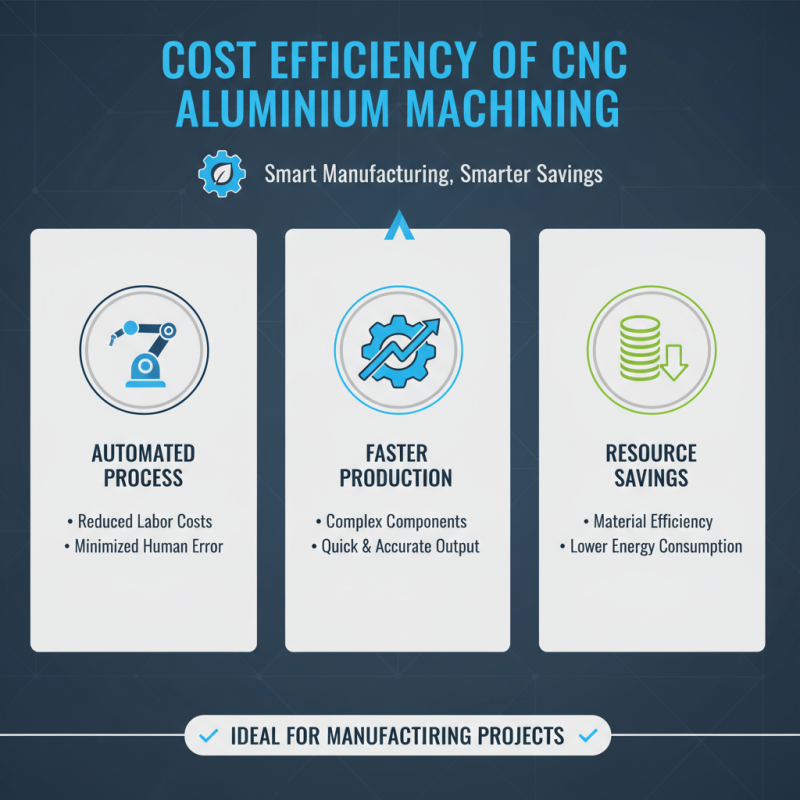

| Benefit | Description | Impact on Project |

|---|---|---|

| Improved Surface Finish | CNC machining delivers high-quality surface finishes that can reduce the need for extensive post-processing. | Reduces labor costs and enhances aesthetic appeal. |

| Precision and Accuracy | CNC machining provides extreme precision, minimizing tolerances to achieve exact specifications. | Ensures better fitting of components and increases product reliability. |

| High Efficiency | CNC machines can operate continuously with minimal downtime. | Faster production times lead to meeting tight deadlines. |

| Complex Geometries | Able to create intricate shapes and designs that are hard to achieve with traditional methods. | Allows for innovative designs that can enhance functionality. |

| Material Versatility | CNC machining can process various aluminum alloys tailored for specific needs. | Enables selection of materials that optimize performance for specific applications. |

| Reduced Waste | CNC machining produces less scrap material compared to traditional machining. | Lower material costs and improved sustainability. |

| Automation Capability | CNC machines can be automated to produce parts without constant human supervision. | Reduces labor costs and improves consistent output. |

| Easy Design Modifications | CNC programs can be easily adjusted to accommodate design changes. | Facilitates flexibility and fast responses to client feedback. |

| Cost Efficiency for Small Batches | CNC machining is cost-effective even for small production runs. | Reduces initial investment compared to tooling for traditional methods. |

| Enhanced Safety | CNC machining processes are more controlled and less hazardous. | Safer work environment minimizes accidents and health risks. |

Increased Production Volume and Speed with CNC Machining Techniques

CNC aluminum machining has transformed the manufacturing landscape, particularly when it comes to enhancing production volume and speed. With its precision and efficiency, CNC (Computer Numerical Control) machining allows for rapid processing of aluminum parts, enabling manufacturers to produce high-quality components in less time than traditional methods. This technological advancement ensures that projects can meet tight deadlines while maintaining exceptional accuracy.

For those looking to leverage CNC machining for their next project, here are some tips to optimize production. First, invest in high-quality aluminum materials that are compatible with CNC processes, as this can greatly affect the machining speed and final output quality. Additionally, consider using advanced CAM (Computer-Aided Manufacturing) software to streamline your design and programming processes. This not only reduces setup time but also facilitates the efficient creation of complex designs that would be challenging to achieve manually.

Finally, it’s essential to regularly maintain your CNC equipment. Proper upkeep will help in maximizing machine efficiency and minimizing downtime, thus maintaining the pace of production. By integrating these practices, manufacturers can significantly boost their production capabilities and capitalize on the benefits of CNC aluminum machining.

Related Posts

-

Discover the Advantages of Using CNC Aluminum in Modern Manufacturing Processes

-

How to Choose the Right CNC Machine for Your Manufacturing Needs

-

Top 10 Benefits of Prototype Manufacturing for Your Business Success

-

What is CNC Machining? A Comprehensive Guide to the Basics and Applications

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing