Best Precision CNC Machining Parts for High Quality Manufacturing Solutions

In the ever-evolving landscape of high-quality manufacturing solutions, precision CNC machining parts have emerged as a cornerstone of modern industry. Renowned expert Dr. Alex Thompson, a leader in the field of advanced machining technology, emphasizes, "The quality of your CNC machining parts directly influences the efficiency and reliability of the entire manufacturing process." This statement underscores the critical importance of precision in creating components that meet the rigorous demands of various applications across sectors such as aerospace, automotive, and medical devices.

As manufacturers seek innovative ways to optimize their production processes, the focus on precision CNC machining parts becomes increasingly vital. These components not only enhance product performance but also contribute to overall cost-effectiveness by reducing waste and minimizing the need for rework. In a world where precision is paramount, investing in top-notch CNC machining solutions is not merely an option but a necessity for businesses aiming for excellence in their manufacturing strategies. By understanding the intricate relationship between component quality and manufacturing success, companies can leverage precision CNC machining parts to push the boundaries of what's possible in their industries.

Best Precision CNC Machining Parts for High Quality Manufacturing Solutions

In the realm of manufacturing, precision CNC machining parts have emerged as a cornerstone for high-quality production solutions. These components are vital in various industries, from aerospace to medical devices, where accuracy and reliability are paramount.

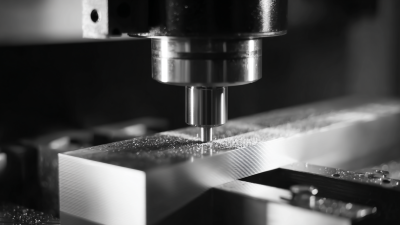

Precision CNC machining enables manufacturers to produce intricate designs with tight tolerances, ensuring that every part meets exact specifications. This capability not only enhances product performance but also reduces material waste and the potential for errors during assembly.

Utilizing advanced CNC machines allows for the seamless integration of various materials, including metals and polymers. The versatility of CNC machining processes, such as milling, turning, and grinding, makes it possible to address a broad spectrum of manufacturing needs.

High-quality CNC parts are often characterized by their durability and consistency, making them ideal for critical applications. Moreover, the adoption of modern software in the CNC machining process aids in optimizing production lines, facilitating faster turnaround times while maintaining stringent quality control throughout the manufacturing cycle.

This synergy between technology and precision machining continues to drive advancements in the industry, delivering significant benefits to manufacturers seeking to enhance their operational efficiency and product quality.

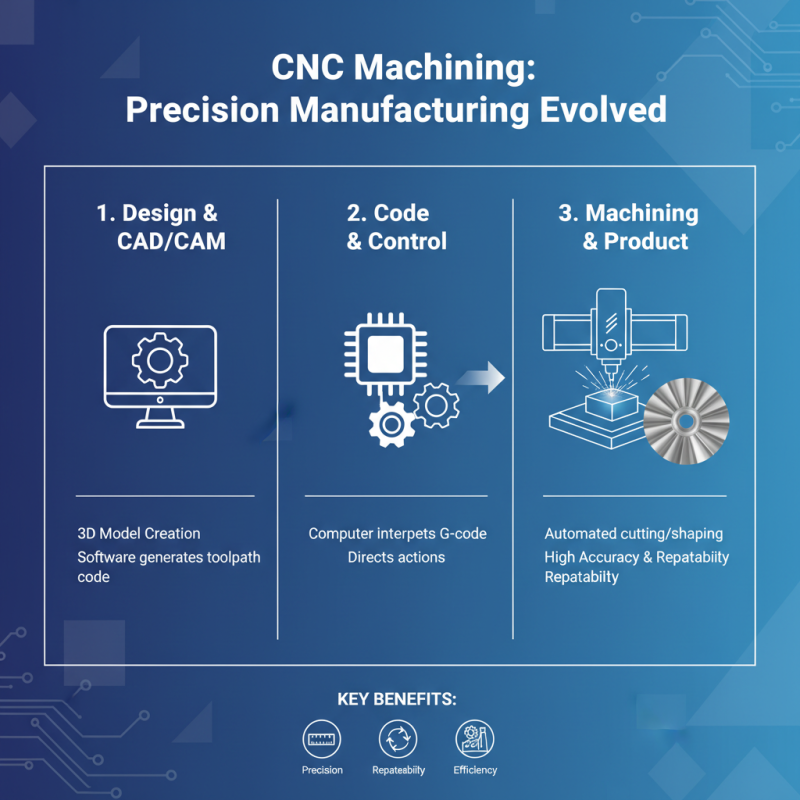

Understanding CNC Machining: Key Principles and Technologies

CNC (Computer Numerical Control) machining has revolutionized the manufacturing landscape by offering precise control over the machining process. At its core, CNC machining involves the use of computer technology to operate machine tools. This allows for high levels of accuracy and repeatability, which is essential in producing high-quality components for various industries. Key principles behind CNC machining include the conversion of a design model into a code that directs the machine on how to cut, shape, or mill the material according to the specified dimensions.

Understanding the essential technologies behind CNC machining is crucial for manufacturers looking to enhance their production capabilities. Techniques such as 3D modeling, G-code programming, and the integration of CAD (Computer-Aided Design) software play significant roles in this process. By leveraging these technologies, manufacturers can streamline their workflow and reduce lead times while ensuring superior part quality.

Tips: One effective way to ensure high precision in CNC machining is to regularly maintain the machinery and update the software used for programming. Additionally, investing in quality materials can greatly impact the end product's durability and performance. Maintaining tight tolerances during the machining process will further enhance the overall precision of the final parts.

Materials Used in Precision CNC Machining: Selection and Properties

Materials play a crucial role in precision CNC machining, significantly impacting the performance and quality of the final product. Common materials used include aluminum, stainless steel, brass, and plastics like nylon and polycarbonate. According to a report by MarketsandMarkets, the global CNC machining market valued at $63.7 billion in 2020 is expected to reach $117.2 billion by 2026, indicating a growing demand for high-quality materials. Each material offers unique properties; for example, aluminum is favored for its lightweight and corrosion resistance, while stainless steel is renowned for its strength and durability, making it suitable for critical applications in the automotive and aerospace industries.

Selection of materials based on their properties is essential for achieving desired outcomes in manufacturing solutions. Mechanical properties such as tensile strength, hardness, and machinability are key factors that influence material choice. A study by the American Society of Mechanical Engineers (ASME) indicates that nearly 60% of machining failures can be attributed to inappropriate material selection. Additionally, thermal properties, such as conductivity and expansion, can affect precision machining processes. Understanding these characteristics helps engineers and manufacturers select the most suitable materials to enhance performance, reduce costs, and achieve tighter tolerances vital for high-quality manufacturing.

Quality Control in CNC Machining: Techniques and Industry Standards

Quality control is a vital aspect in the realm of CNC machining, especially when producing precision parts for high-quality manufacturing solutions. According to a recent industry report by the Manufacturing Institute, nearly 80% of manufacturers cite quality control as a top priority, and the implementation of stringent quality assurance protocols can dramatically improve production consistency and defect rates. Techniques such as statistical process control (SPC) and Six Sigma methodologies have been widely adopted to analyze process data and maintain quality standards throughout production, ensuring that the final products meet or exceed client expectations.

Furthermore, adherence to industry standards such as ISO 9001 and AS9100 is crucial for maintaining a reliable quality management system in CNC machining operations. These standards set the benchmark for consistent product quality and effective process management, with studies showing that companies that comply with international quality standards experience up to 15% lower operational costs and significantly higher customer satisfaction rates. As the demand for precision CNC machined parts continues to rise, investing in quality control processes not only enhances competitiveness but also fosters long-term relationships with clients who prioritize excellence in their manufacturing solutions.

Applications of Precision CNC Machined Parts in Various Industries

Precision CNC machined parts are integral to a multitude of industries, providing high-quality manufacturing solutions that enhance performance and efficiency. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach USD 100.25 billion by 2025, growing at a CAGR of 6.6% from 2020. This growth is driven by increased demand for precision components in various applications, including aerospace, automotive, medical devices, and electronics. Each of these sectors relies on precision machining to produce parts that meet stringent quality standards, ensuring safety and reliability.

In the aerospace industry, for instance, precision CNC machined parts are essential for manufacturing components that require extreme accuracy and lightweight characteristics. The Federal Aviation Administration (FAA) reported that a significant percentage of aircraft maintenance issues stem from machining defects, highlighting the importance of precision in this field. Meanwhile, in the medical device sector, the global market for precision machined parts reached USD 8.25 billion in 2021 and is expected to grow substantially as healthcare technology evolves. These parts play a crucial role in the fabrication of surgical instruments, implants, and diagnostic equipment, where precision and reliability are paramount. As industries continue to advance, the role of precision CNC machining will undoubtedly expand, reinforcing its position as a critical component in high-quality manufacturing solutions.

Applications of Precision CNC Machined Parts in Various Industries

This chart illustrates the market share of precision CNC machined parts across different industries. The data showcases how essential these machined parts are in sectors such as Aerospace, Automotive, Electronics, Medical, and Industrial Equipment.

Related Posts

-

Top 10 Best CNC Machined Parts to Order for Your Projects in 2023

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

2025 Top 5 High Precision Machining Trends and Technologies Revolutionizing Manufacturing

-

2025 Top 10 5 Axis CNC Machines Revolutionizing Precision Manufacturing

-

Why Accurate CNC Machine Quotations Are Essential for Cost-Effective Manufacturing

-

Discover the Advantages of Using CNC Aluminum in Modern Manufacturing Processes