Discover the Advantages of Using CNC Aluminum in Modern Manufacturing Processes

In the rapidly evolving landscape of modern manufacturing, the utilization of CNC aluminum has emerged as a game-changer for various industries. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach $100 billion by 2025, demonstrating a significant shift towards advanced manufacturing technologies that enhance precision and efficiency.

CNC aluminum, in particular, has gained popularity due to its lightweight and corrosion-resistant properties, making it an ideal choice for industries ranging from aerospace to automotive. Additionally, a study by Grand View Research indicates that the aluminum market size is expected to experience substantial growth, driven by increasing demand for high-performance materials. This emphasizes the necessity for manufacturers to embrace CNC aluminum solutions to remain competitive while optimizing production processes.

CNC aluminum, in particular, has gained popularity due to its lightweight and corrosion-resistant properties, making it an ideal choice for industries ranging from aerospace to automotive. Additionally, a study by Grand View Research indicates that the aluminum market size is expected to experience substantial growth, driven by increasing demand for high-performance materials. This emphasizes the necessity for manufacturers to embrace CNC aluminum solutions to remain competitive while optimizing production processes.

By exploring the advantages of CNC aluminum, businesses can leverage its benefits to improve product integrity, reduce waste, and streamline operations in an ever-demanding market.

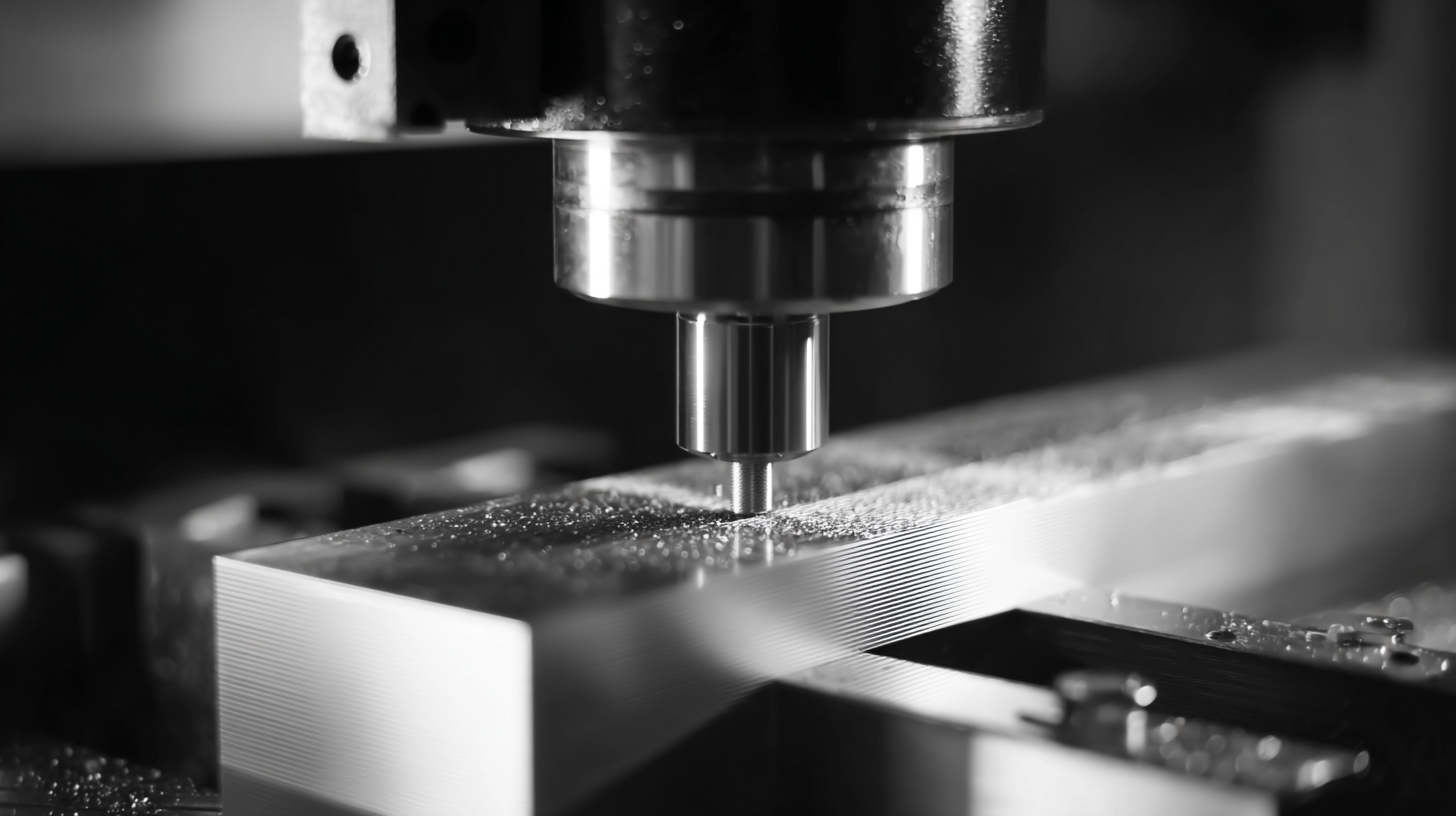

Benefits of CNC Aluminum: Enhanced Precision in Manufacturing

CNC aluminum machining offers exceptional precision, making it a sought-after choice in modern manufacturing processes. The use of computer numerical control (CNC) technology allows for the creation of intricate designs with tight tolerances that would be nearly impossible to achieve through traditional machining methods. This level of accuracy ensures that each component manufactured meets exact specifications, reducing the likelihood of errors and the need for costly rework.

CNC aluminum machining offers exceptional precision, making it a sought-after choice in modern manufacturing processes. The use of computer numerical control (CNC) technology allows for the creation of intricate designs with tight tolerances that would be nearly impossible to achieve through traditional machining methods. This level of accuracy ensures that each component manufactured meets exact specifications, reducing the likelihood of errors and the need for costly rework.

Moreover, CNC aluminum systems can operate at high speeds without sacrificing quality. This capability enhances productivity as manufacturers can produce a larger volume of parts in a shorter timeframe. The lightweight nature of aluminum combined with CNC's precise cutting techniques makes it ideal for industries that require both strength and lightweight properties in their components, such as aerospace and automotive.

Overall, the benefits of enhanced precision in CNC aluminum machining not only streamline manufacturing processes but also contribute to higher-quality outputs, setting a new standard in the industry.

Cost Efficiency of CNC Aluminum Compared to Traditional Methods

When it comes to modern manufacturing processes, CNC aluminum stands out for its cost efficiency compared to traditional methods. Traditional machining often involves a labor-intensive process with higher scrap rates and longer production times. In contrast, CNC (Computer Numerical Control) machining allows for precision cutting and shaping, minimizing waste and reducing the overall cost of production. This not only leads to significant savings but also enhances the speed of project completion, making it a preferred choice for manufacturers aiming to stay competitive.

Tip: Consider investing in software that can optimize machining paths. This helps in reducing material waste and improving machining speed.

Moreover, the versatility of CNC aluminum contributes to its cost efficiency. It can be easily molded into various shapes and sizes, accommodating a wide range of applications from automotive to aerospace. This flexibility translates into lower setup costs and less need for custom tooling, allowing manufacturers to adjust quickly to market demands without overspending.

Tip: Regular maintenance of CNC machines can prolong their lifespan and efficiency, ultimately leading to reduced operational costs over time.

Lightweight and Durable Properties of CNC Aluminum Technology

CNC aluminum technology has revolutionized modern manufacturing by offering remarkable lightweight and durable properties. Aluminum, known for its high strength-to-weight ratio, allows manufacturers to create components that are not only lighter but also strong enough to withstand demanding applications. This characteristic is particularly beneficial in industries such as aerospace and automotive, where reducing weight can lead to significant improvements in fuel efficiency and performance.

Moreover, the CNC (Computer Numerical Control) process enhances the precision and accuracy of aluminum components, ensuring they meet stringent specifications and tolerances. This precision is vital in high-performance applications, where even minute deviations can affect functionality. The durability of CNC aluminum parts also ensures longevity and resistance to wear and corrosion, which can ultimately lower maintenance costs and extend the lifespan of manufactured goods. As a result, embracing CNC aluminum technology presents manufacturers with a competitive edge in delivering superior products while maintaining efficiency and sustainability in their operations.

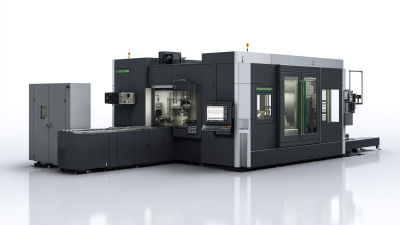

Versatility of CNC Aluminum in Various Industrial Applications

CNC aluminum has become a pivotal material in numerous industrial applications due to its remarkable versatility. According to a report by Grand View Research, the global aluminum market was valued at USD 155 billion in 2020 and is projected to grow at a CAGR of 6.1% from 2021 to 2028. This growth is largely driven by the demand for lightweight yet strong materials in sectors such as automotive and aerospace. CNC (Computer Numerical Control) machining provides the precision necessary to produce complex shapes and components that meet exacting industry standards, ensuring that manufacturers can deliver high-quality products efficiently.

In the automotive industry, for example, CNC aluminum is favored for engine parts and lightweight structures, contributing to fuel efficiency and overall performance. The lightweight nature of aluminum reduces the vehicle's overall weight, which helps meet stringent emissions regulations while enhancing speed and agility. Additionally, a report from the International Aluminum Institute highlights that aluminum's recyclability adds another layer of sustainability, appealing to modern manufacturers focused on reducing their environmental impact. The integration of CNC machining with aluminum not only supports various manufacturing processes but also enables innovation in designs, making it a versatile choice for industries ranging from medical devices to electronics.

Future Trends in CNC Aluminum Usage for Advanced Manufacturing

The future of CNC aluminum usage in advanced manufacturing is poised for significant evolution, driven by technological advancements and the growing demand for lightweight, durable materials. As industries continue to explore innovative solutions, CNC machining of aluminum allows for unparalleled precision and flexibility, enabling manufacturers to create complex geometries that meet the increasing requirements for efficiency and performance. This capability is particularly advantageous in sectors such as aerospace and automotive, where weight reduction is critical to improving fuel efficiency and reducing emissions.

Additionally, the integration of smart technologies, such as IoT and AI, into CNC machining processes is likely to enhance productivity and reduce operational costs. These advancements promise to optimize machining parameters in real-time, leading to improved quality control and reduced material wastage. As manufacturers adopt these cutting-edge methods, the versatility of CNC aluminum is expected to further expand, making it an essential material for futuristic production environments. The synergy between CNC technology and aluminum will not only streamline production processes but also foster the development of innovative products that push the boundaries of what is possible in modern manufacturing.

Related Posts

-

Understanding the Innovation Behind CNC Parts in Modern Manufacturing Techniques

-

Revolutionizing Industry with Advanced Machining Solutions for Modern Manufacturing

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing