How to Achieve Success in Precision Manufacturing Techniques?

In the rapidly evolving world of precision manufacturing, success often hinges on the ability to adapt and innovate. The techniques employed in this field can shape a company’s future, influencing everything from product quality to operational efficiency. Precision manufacturing is not just about machines; it’s a mindset.

Businesses must embrace advanced technologies like automation and data analytics. These can drive precision and enhance productivity. However, a common pitfall lies in over-relying on technology. While machines can improve output, human skill remains irreplaceable. Training and development for staff are crucial for forging a skilled workforce capable of operating sophisticated tools.

Moreover, continuous improvement is vital. Many processes may initially yield less than desired results. Reflecting on failures can uncover hidden opportunities. Engaging teams in problem-solving fosters innovation. This creates an environment where precision manufacturing thrives, ultimately leading to success in a competitive landscape.

Understanding Precision Manufacturing Techniques and Their Importance

Precision manufacturing techniques are essential in today’s competitive landscape. They focus on creating parts and products with high accuracy and minimal variances. This level of precision is crucial in industries like aerospace, automotive, and electronics, where even the smallest defect can have severe consequences. When manufacturers utilize these techniques, they enhance product reliability and performance, which directly impacts customer satisfaction.

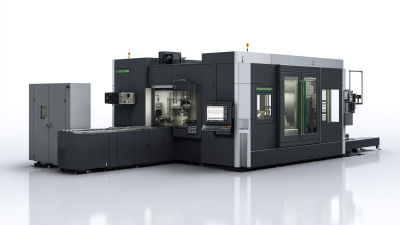

Understanding these techniques can lead to better decision-making. For instance, components made with laser cutting or CNC machining often demonstrate superior quality. However, some companies struggle with the implementation of these methods. They may invest in advanced machinery but fail to properly train staff. This can result in wasted resources and time. Additionally, over-reliance on technology without human oversight can lead to overlooked flaws. Balancing technology with skilled artisanship is vital.

Precision manufacturing is not just about technology. It also requires a mindset focused on continuous improvement. Companies should foster an environment where employees feel empowered to suggest changes and improvements. Regular audits and feedback loops are necessary but often underutilized. Embracing a culture of reflection strengthens precision and helps achieve long-term success.

Achieving Success in Precision Manufacturing Techniques

This chart illustrates the importance levels of various key aspects in achieving success in precision manufacturing techniques. Efficiency stands out as the most critical element, followed closely by quality control. These insights can guide manufacturers in prioritizing their strategies for optimal outcomes.

Key Components of Successful Precision Manufacturing Processes

Precision manufacturing demands a blend of innovation, technology, and meticulous attention to detail. Successful processes hinge on clear communication among teams and a commitment to quality. When engineers and operators can easily exchange information, they resolve problems swiftly. This collaboration leads to fewer errors. Yet, even in the best environments, miscommunication can happen. Teams must regularly check in to align expectations and objectives.

Another critical component is the use of advanced tools and equipment. Selecting the right machinery can vastly improve production efficiency. However, relying too heavily on technology can also backfire. Machines can fail, leading to costly downtime. Regular maintenance is essential, but it’s easy to overlook. Training staff to handle these tools is equally important. Skilled workers enhance not just productivity but also ensure safety in the workplace.

Data collection plays a pivotal role in precision manufacturing. Analyzing production metrics helps identify inefficiencies. These insights guide improvements over time. Yet, organizations often struggle with data integration. It's a challenge to sift through numbers and extract actionable insights. Regularly revisiting your data strategy is necessary. Reflecting on what works well and what doesn’t helps refine manufacturing processes, creating a path to sustained success.

Best Practices for Implementing Precision Manufacturing Techniques

Precision manufacturing reflects a significant shift in how industries operate. Implementing best practices is essential for achieving success. According to a recent report by the International Society of Automation, organizations that embrace precision techniques have seen productivity increase by an average of 30%. This statistic highlights the potential for manufacturers to improve efficiency dramatically. However, the transition to precision manufacturing can often lead to challenges.

One common issue is the need for skilled workers. Many companies report a shortage of adequately trained personnel. This gap can hinder the implementation of advanced techniques. Investing in training programs is necessary. A study from the SME Foundation shows that 40% of manufacturing firms cite lack of skilled labor as their biggest obstacle. Moreover, integration of technology is crucial. Data analytics tools can help track performance, but many firms struggle to fully leverage these resources.

Moreover, understanding customer requirements is vital. Collecting precise data on client expectations can lead to better outcomes. Companies often overlook this step, resulting in discrepancies between product delivery and client needs. The quality of the final product suffers without this critical feedback loop. Overall, refining these practices may require reflection and adaptation, but the rewards are worth the effort.

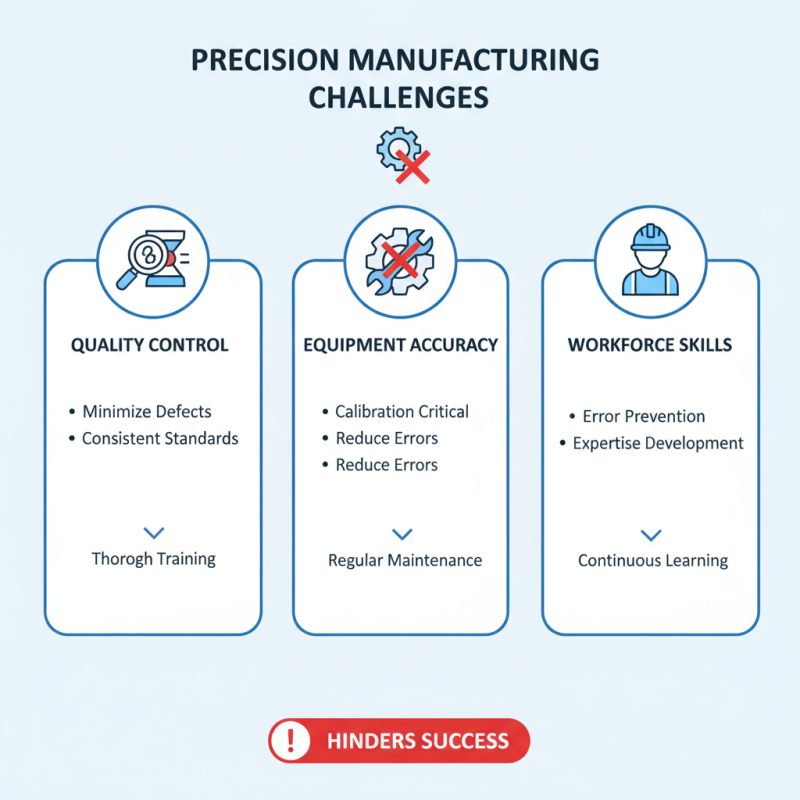

Challenges in Precision Manufacturing and How to Overcome Them

Precision manufacturing faces several challenges that can hinder success. One major issue is maintaining high quality in every step of the process. Even minor errors can lead to significant defects. Workers need thorough training to minimize mistakes. Equipment should be regularly calibrated to ensure accuracy.

Another challenge is the integration of new technologies. Companies often struggle to keep up with advancements. This can lead to outdated practices that slow production. Embracing change is crucial. However, changes can be difficult to implement. Employees may resist new systems or fear job loss. Clear communication can help ease these transitions.

Supply chain disruptions also pose significant hurdles. Unexpected delays can stall production lines. Companies should build strong relationships with suppliers to mitigate risks. Diversifying sources can reduce dependencies. A flexible approach is necessary for quick adaptation. In this increasingly complex landscape, constant evaluation is essential for growth.

Future Trends in Precision Manufacturing and Their Implications for Success

Precision manufacturing is evolving rapidly. Emerging technologies reshape how products are made. Automation, for instance, enhances efficiency but also raises concerns. Workers may fear job displacement. Balancing tech integration with workforce needs is essential.

Additive manufacturing gains traction. It allows for complex designs without increasing costs. However, quality control becomes more challenging. Companies must invest in training and develop new protocols. Not all organizations are prepared for this shift.

The future also emphasizes sustainability. Companies face pressure to reduce waste and energy use. Adopting greener practices is not just beneficial but necessary. Yet, some may resist change due to initial costs. This creates a gap between those who innovate and those who lag behind. Each step forward demands reflection on both successes and failures.

Related Posts

-

Revolutionizing Industry with Advanced Machining Solutions for Modern Manufacturing

-

10 Essential Tips for Achieving High Precision Machining Success

-

How to Choose the Best Precision CNC Machining Services for Your Projects

-

Unlocking the Future: How Precision CNC Technology is Revolutionizing Manufacturing

-

Unlocking Innovation: How Precision CNC Machining Parts Revolutionize Modern Manufacturing

-

2025 Top 5 High Precision Machining Trends and Technologies Revolutionizing Manufacturing